Call Our Team For Alternatives to:

The Clark Solutions sales team works OEM applications every day.

For specialized products, decades of application experience, innovation, and first-in-class person to person support contact us.

Flow Sensors that should be candidates for your applications:

Model PFA Turbine Flow Sensor

TURBINE FLOW SENSOR PFA (0045, 0085, 00125)

PFA WETTED PARTS, F.S. RANGES OF 2 & 20 LPM, FREQUENCY OUTPUT

The PFA Turbine Flow Sensor has low flow sensing capabilities in a wide range of applications, and is suitable for clear, opaque, neutral, corrosive and aggressive liquids including fuel.

An ultra-lightweight turbine follows the fluctuation of flow very accurately and generates a high resolution IR reflected digital output signal. Aggressive media can be measured, as the only wetted materials are PFA and a ruby bearing.

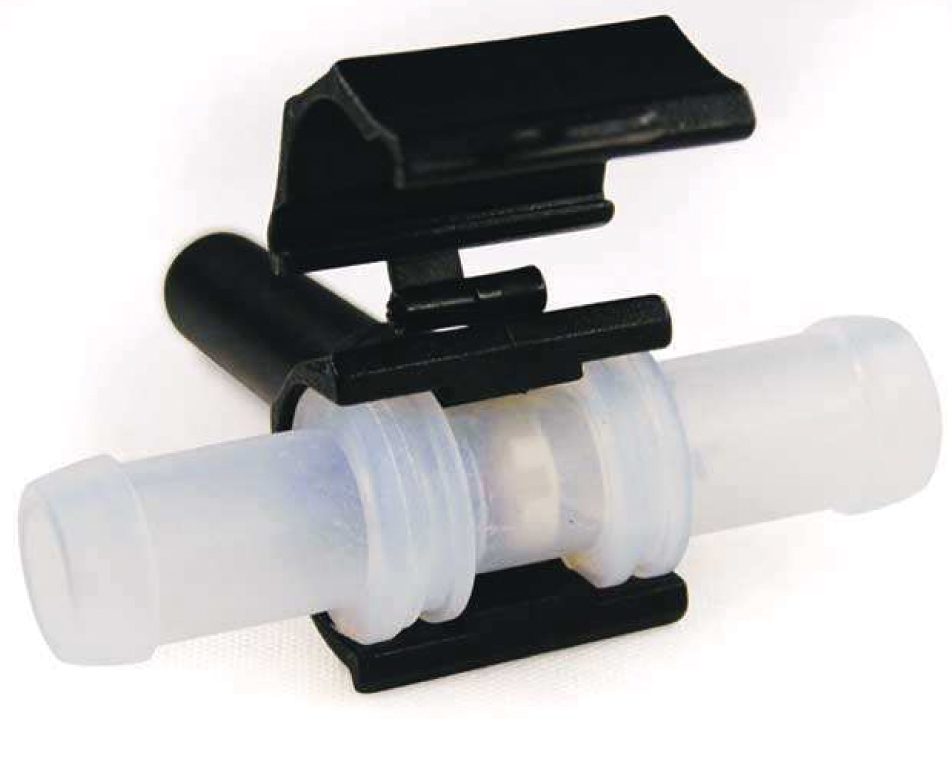

Model PFAD Disposable Turbine Flow Sensor

DISPOSABLE TURBINE FLOW SENSOR PFAD

PFA WETTED PARTS, F.S. RANGES OF 2 & 20 LPM, FREQUENCY OUTPUT

The PFAD Disposable Turbine Flow Sensor has been developed to perform a fast exchange of the flow tube to accommodate hygienic applications in the pharmaceutical industry and other applications where a field replaceable sensor is desirable. It is suitable for clear, opaque, neutral, corrosive and aggressive liquids.

A field replaceable ultra-lightweight turbine assembly follows the fluctuation of flow very accurately and generates a high-resolution IR reflected digital output signal. Two housing styles, “clip” and “click” types are offered.

Aggressive media can be accommodated as the only wetted materials are PFA and a ruby bearing.

Model PVDF Disposable Turbine Flow Sensor

DISPOSABLE TURBINE FLOW SENSOR PVDF

PVDF WETTED PARTS, F.S. RANGES OF 2 & 20 LPM, FREQUENCY OUTPUT

The PVDF Disposable Turbine Flow Sensor has been developed to perform a fast interchange of the flow tube to accommodate hygienic applications in the medical, pharmaceutical, and bio-technological industries. It has low flow capabilities and high-resolution square wave output. The flow tube can be sterilized to 140°C (284°F) and is gamma radiation resistant up to 50 kGy. These features make this model ideal for monitoring and controlling fluid flows in sanitary applications.

A field replaceable ultra-lightweight turbine assembly follows the fluctuation of flow very accurately and generates a high-resolution IR (Infrared) reflected digital output signal.

Model SS Stainless Steel Turbine Flow Sensor

STAINLESS STEEL TURBINE FLOW SENSOR SS (0045, 0085, 00125)

SS WETTED PARTS, F.S. RANGES OF 2, 20, & 40 LPM, FREQUENCY OUTPUT

Model SS Stainless Steel Turbine Flow Sensor has low flow sensing capabilities in a wide range of applications and is suitable for clear, opaque, neutral, corrosive and aggressive liquids. It has a rugged stainless steel housing and is available with threaded or Tri-Clamp end connections.

An ultra-lightweight turbine follows the fluctuation of flow very accurately and generates a high-resolution IR reflected digital output signal.

K-factors (pulses per liter) are factory determined and provided for each flow tube. Customer specified K-factors can be accommodated and are programmed at the factory.

0045 & 0085 Disposable Flowmeter Tube Holder System

F.S. RANGES OF 2 & 20 LPM, FREQUENCY OUTPUT, FOR USE WITH EQUFLOW FLOW TUBES

These flowmeters house Equflow disposable PFA and PVDF turbine flowtubes. They have low flow capabilities useful in a wide range of

flow processes.

The idea is to perform fast exchange of the flow tube in single-use applications. Clinical, analytical, bio-tech and pharmaceutal chemistry

equipment applications, where frequent tube changes are necessary to avoid contamination of the process, are the typical use.

CALL NOW to speak with a Sales Engineer

To discuss your application and our ability to meet your needs

Why Clark Solutions?

For over 35 years, Clark Solutions has represented and distributed specialized components for the HVAC, Original Equipment Manufacturer, and Process Engineering communities. Calling on our many years of experience and factory engineering support, our knowledgeable sales team works daily to evaluate every new application for component suitability and selection. We are committed to customer satisfaction from application concept and engineering through procurement and fulfillment.

Who Is Clark Solutions?

Clark Solutions has leveraged years of success to become a trusted factory representative for over 25 companies located here in the USA, as well as eight international partners plus our own manufactured products. Our team represents and supports the world’s best in flow, pressure, level, temperature control products, and a full range of small pumps and specialty valves. Each product line has been chosen to fill unique niches and specialized application needs. We work daily to match our customer’s specific requirements to quality components.